Australian Battery Industry Association: Prioritising lithium battery safety

The Australian Battery Industry Association explains how it works to ensure the highest standards of lithium battery safety within Australia.

Lithium-ion batteries for business, recreational and marine use are growing in popularity due to their lightweight and durable properties. In Australia, they are a popular alternative to meet marine and recreational needs driven by a marine environment covering 34,000km of coastline and a diverse, sparsely populated outback geography. The switch to cordless and lower emissions (not diesel) power equipment is also contributing to the rapid growth of lithium battery applications in the industrial equipment, backup power, trade, and power tool market segments.

As these batteries increase in popularity, the Australian Battery Industry Association (ABIA), established in 1990, is advocating and driving best practices to strengthen safety for everyone in the lithium battery value chain. ABIA’s mission is to: ‘Collectively ensure a trusted, transparent and sustainable battery industry in Australia.’

Alongside its 25 members, the association brings significant and diverse experience drawn from across Australia’s A$1.8bn battery market. Three of the top five battery market leaders are active participants in ABIA, together with leading aftermarket battery distributors and sales businesses.

In the lithium-ion battery segment, ABIA members cover designers, developers, importers, distributors, and manufacturers of mid-size lithium-ion batteries for a wide variety of Australian conditions. The predominate chemistry is lithium iron phosphate (LFP) in 6V, 12V, 24V, 36V and 48V capacity for automotive, industrial, marine, and recreational activities.

This industry capability is informing the development of lithium battery safety settings. ABIA and its members are also working to minimise environmental impacts throughout the battery life cycle.

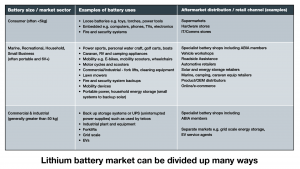

To put this in context, the battery market is diverse and broadly segmented by application, as shown in the following diagram. There is no standardised categorisation of the lithium-ion battery market and there are other commonly used descriptions to describe segments of the battery market. Chemistry is also a frequently used way to consider battery distribution channels.

Product standards are critical for improving battery safety

The growing prevalence of lithium batteries is raising questions about product performance, safety and the key design components of the battery which support safety. ABIA is advocating strongly for minimum battery standards to ensure that inbuilt safety features are working, and battery construction minimises fire risks. This does not cover electric vehicles (EVs) and energy storage batteries, which are often subject to different standards.

At a member forum held in May, discussions focused on several key factors to consider for lithium battery safety, as detailed below.

Temperature sensors

The temperature sensor monitors the battery temperature to enhance battery safety and prevent overheating, which can result in a battery fire. When connected to the battery management system, if the sensor detects overheating, it can shut down the battery to minimise the risk of fire. Not all batteries will have temperature sensors or well-connected sensors.

Battery Management System

Commonly known as the BMS, the system is primarily designed to protect lithium battery safety by checking for over and undercharging, thereby preventing damage. It can undertake a range of additional roles, such as shutting down the battery if there is a risk, e.g., overcharging/discharging, of the battery being damaged; communicating information with external monitoring systems; and checking for other system health issues, such as loose connections.

There is no BMS standard and there can be a high variance between BMS capability and functions. It is always important to check whether the battery has a BMS and, if so, what functions are included in the BMS. Monitoring overcharging is no good if there is not also a shutdown function.

Battery cells: New versus second life cells

Lithium batteries sold in the Australian market may not contain all new cells. Examples are emerging batteries which contain a mix of new and second-life battery cells, even in brand new batteries. It is important to ask the product manufacturer or distributor whether the battery contains only new cells or a mix of new and second life.

Construction

There is no standard for lithium battery construction – the assembly of all the battery components into the finished product. This means that the construction quality can vary for features such as insulation on terminals to prevent short circuits; the amount of filling to protect battery packs and cells from movement; and wire management, how the BMS is connected to the battery components.

As batteries are pre-assembled, it is difficult to assess these by looking at the battery. That is why ABIA suggests customers ask the battery supplier to provide independent test certificates to determine whether the battery has been tested to UN38.3 for safe transport and other international battery safety test standards such as IEC 62133, IEC 62619, or UL1642.

Priorities for lithium battery safety

The key focus of the Australian battery market is the consumer regulator’s (Australian Competition and Consumer Commission) inquiry into lithium-ion battery issues. This is one of the regulator’s seven product safety priorities for 2022/23, which also includes button battery safety standards.

The inquiry is focusing on scoping safety issues and identifying potential hazard prevention strategies. ABIA is supporting the inquiry by providing insights into technical and product quality matters.

ABIA’s priority is to set mandatory, minimum standards to improve lithium battery safety and product quality. However, this cannot happen in a vacuum and requires a package of measures that also include information and education. ABIA recommends that product standards should be supported by:

- Accelerated development of lithium-ion battery labelling standards;

- Improving information for consumers on battery management systems as these are critical to how a battery will operate and what happens when it fails; and

- Ongoing public education campaigns for consumers to support best practice approaches to using and charging a battery over a product’s life as well as disposal of a battery at its end of life.

The largest part of a battery’s life is in the hands of the consumer, and therefore, consumer handling and management of the battery will have a significant impact on battery outcomes. Reminders about safe usage, as well as disposal at its end of life, will be critical to reduce the risks of fires in homes and waste facilities.

Industry initiatives to improve standards

ABIA is not waiting for regulatory solutions to improve safety and industry standards. The association is undertaking workstreams to deliver better outcomes for customers and industry in the automotive, marine, industrial, and recreational battery segments of the market.

For consumers, this programme of work is providing them with information about what to look for in battery products, guidance such as certification tests for lithium-ion batteries and online tools to help them make an informed decision about the quality of the product they are purchasing. The ABIA website was revamped in 2022 to provide a customer-focused, user-friendly interface.

For industry, ABIA is:

- Exploring the development of a lithium iron phosphate battery endorsement symbol which includes focusing on whether products have undertaken independent testing and support end-of-life battery management;

- Providing information sessions on battery safety topics;

- Looking to develop guidance on warehousing, storage and handling of batteries above 100 amp hours, including information on recycling packaging, safety and collection; and

- Considering best practice guidance on how lithium-ion batteries could meet international testing requirements.

In Australia, one of the greatest challenges in developing an endorsement symbol for companies assembling batteries locally is the lack of an independent testing facility. ABIA hopes that the National Battery Testing Centre, which is currently under development, will prioritise work in this area.

Whilst the industry will continue to drive its own actions, it is closely watching for the release of the consumer regulator’s findings on its inquiry into lithium battery safety issues. Mandatory standards and support for industry with consumer education activities would be a great outcome. The regulator’s report will be a pivot point for setting industry priorities for the next few years.