New ‘robomapper’ robot developed to improve efficiency of solar cells

Researchers have developed a new robot that can rapidly identify new perovskite materials to improve the efficiency of solar cells.

The new robot, called RoboMapper, is capable of conducting experiments more efficiently to develop a range of semiconductor materials with desirable qualities.

“RoboMapper allows us to conduct materials testing more quickly, while also reducing both cost and energy overhead – making the entire process more sustainable,” said Aram Amassian, corresponding author of a paper on the work and a professor of materials science and engineering at North Carolina State University.

The paper, ‘Sustainable Materials Acceleration Platform Reveals Stable and Efficient Wide Bandgap Metal Halide Perovskite Alloys,’ is published in the journal Matter.

Robomapper makes searching for new materials more efficient and cost-effective

Conventional materials research needs a researcher to prepare a sample and then test this using different instruments. This involves placing, aligning, and calibrating samples to collect the data.

Previously, automating this process has relied on automating the assembly line with one sample per chip moving through the data collection process. This improves speed. However, each step has to be done with one sample at a time.

“RoboMapper also automates this process, but places dozens of samples on each chip by miniaturising the material samples with the help of modern printing,” Amassian said.

“It still performs each step of the data collection process, but it does so for multiple materials in parallel, saving time and energy.”

“This makes searching for new materials far more efficient, more cost-effective, and more sustainable in terms of our carbon footprint,” said Tonghui Wang, lead author of the paper and a PhD student at NC State.

“It’s nearly ten times faster than previous automated techniques.”

RoboMapper compared with traditional materials research

To prove the performance of the new robot, the team evaluated the environmental impact of traditional materials research and data collection. This was then compared with the RoboMapper.

“It was remarkable to find that characterisation is the major source of greenhouse gas emissions in materials research,” said environmental economist Lucía Serrano-Luján, co-author of the paper and a researcher at Rey Juan Carlos University and the Technical University of Cartagena.

“The RoboMapper’s ability to streamline the data collection process by placing dozens of materials on the same chip reduced greenhouse gas emissions tenfold.”

The team first focused on perovskite materials

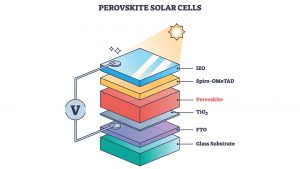

To demonstrate the usefulness of the new robot, the researchers first focused on perovskite materials. Perovskites are better than silicon at absorbing light, meaning that they can be thinner and lighter without sacrificing the cell’s ability to convert light into electricity.

Because of this, they are a focal point for research into next-generation solar cells.

The researchers specifically focused on perovskite stability – one of the biggest challenges in the field.

“Basically, the challenge is that perovskite materials tend to degrade when exposed to light, losing the properties that made them desirable in the first place,” Amassian said.

“We’re looking for ways to engineer these materials so that they are stable – meaning they retain their desirable properties for a long time, even when exposed to light.”

During the new robot’s proof-of-concept demonstration, the researchers made their first significant finding.

RoboMapper was tasked to identify whether an alloy was suitable for boosting solar cell efficiency

RoboMapper’s tests were designed to identify whether an alloy was suitable for tandem solar cells. This means whether:

- It had the crystalline structure of a perovskite;

- It had a desirable set of optical characteristics known as the band gap; and

- It was stable when exposed to intense light.

This data was then used to construct a computational model that identified a specific alloy composition with the best combination of desired attributes.

The team made the desired alloy with the new robot and conventional laboratory techniques. These methods were both tested.

“We are able to quickly identify the most stable composition from a possible set of perovskite alloys at a target band gap using the specific suite of elements we confined ourselves to for this proof-of-concept work,” Amassian said.

“The material we identified using RoboMapper also turned out to be more efficient at converting light into electricity in solar cell devices. Our conventional techniques validated the results from RoboMapper.

“One reason RoboMapper’s experiments were able to produce such useful data is that the specific suite of experiments we used is based on previous work that informs our understanding of the relationship between what we can observe in optical tests and the stability of perovskite materials.

“Next steps for this work include expanding the range of potential alloys for testing in RoboMapper,” Amassian said.

“We’re open to working with industry partners to identify new materials for photovoltaics or other applications. And with support from the Office of Naval Research, we are already using RoboMapper to advance our understanding of materials for both organic solar cells and printed electronics.”